<

Products Information

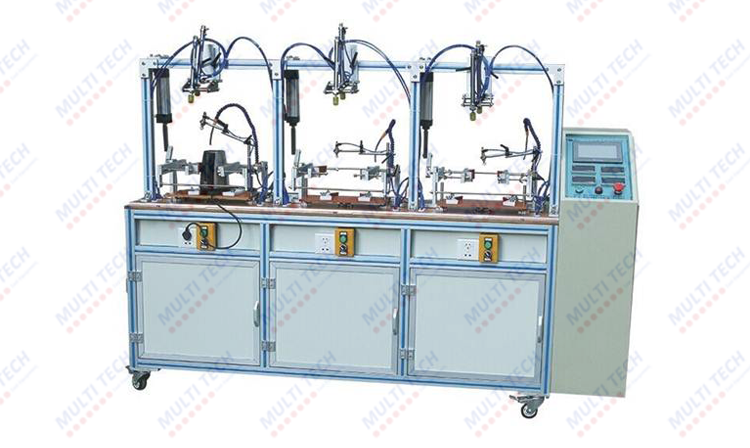

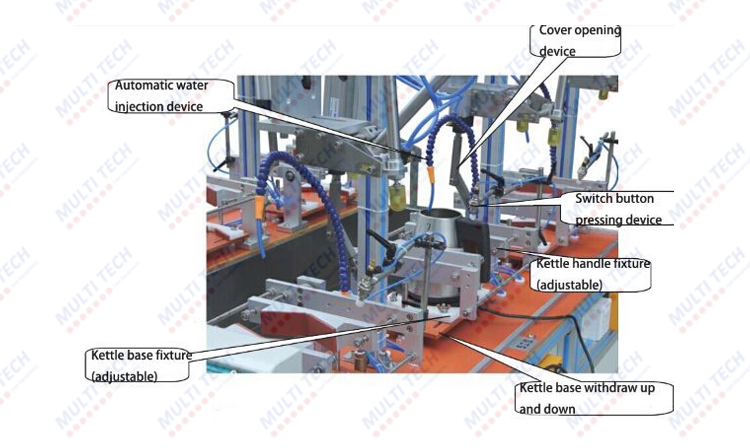

The electric water kettle tester is designed and manufactured according to IEC 60335-2-15 clause 19.101, 19.102, 22.106 and etc. It is suitable for comprehensive lifespan testing of various types of conventional cordless electrothermal kettle, complete simulation of artificial water boiling mode.

The whole without staff care, failure alarm. Each station configured independently, without mutual interference. Very low fault rate.

Technical parameters:

| Power supply | 220 V, 50 Hz or 110V, 60Hz | |

| Test samples | Conventional cordless electrothermal kettle, can be customized for special test samples | |

| Application | comprehensive lifespan test for various types of conventional cordless electrothermal kettle | |

| Work station | 3 workstations, 6 workstations (single/double row), 10 workstations(single/double row), can be customized | |

| Display mode | Touch screen | |

| The specific function Technical parameters | Basic functions | Contains five functions: dry heating (self cooling), dry heating (water cooling), withdraw (without current), withdraw (with current), cyclic boiling water. |

| 1.Dry heating (self cooling): start--kettle pouring-kettle back to origin-- dry heating end (temperature controller jumped) --natural cooling to the | ||

| thermostat reset -- cyclic dry heating | ||

| 2.Dry heating (water cooling): | ||

| Start -- kettle pouring -- began to dry heating -- dry heating end (thermostat trip)- | ||

| - water cooling to the thermostat reset (water volume adjustable) -- kettle pouring-- cyclic dry heating kettle; | ||

| 3.Withdraw (without current): Start -- began to withdraw (cycle work) | ||

| 4.Withdraw (with current):Start -- injecting water (water volume adjustable) -- withdraw (with current) -- cycle work--change the water interval (can be set times) -- cycle work | ||

| 5.Cyclic boiling water: Start--kettle pouring-kettle back to origin--injecting water (can set the injection water volume)--heating and boiling water--after the water is boiled (thermostat trip)---kettle pouring --kettle back to origin--cycle work | ||

| Uses PLC and touch screen control system, operation is stable, maintenance is simple and convenient. The parameter setting and each station working state information can be controlled and displayed on the touch screen. | ||

| With independent design life detection board to monitor products working state, alarm occurs when there is abnormal and fault. | ||

| The equipment can automatically count, the test times can be set, when it reaches to the preset value, the equipment will stop working. | ||

| Control system | ||

| Alarm function | With fault alarm and counting alarm | |

| Safety protection | with leakage protection and undervoltage protection safety devices | |

| Efficiency | Related with the sample’s actual working time, each action control time can be set. | |

| Material | The frame adopts aluminum alloy square tube, door and panels adopt baking varnish, the main water contact parts adopt 304 stainless steel or aluminum alloy, water pumpto add water. | |

| Air source | This machine needs compressed air, air pressure: | |

| 0.4MPa -0.6MPa | ||

| Machine power | The control system is not higher than 1.5Kw | |

| Test mode | 1) Dry heating mode (self cooling) | |

| 2) Dry heating mode (water cooling) | ||

| 3) Withdraw mode (without current) | ||

| 4) Withdraw mode (with current) | ||

| 5)Water boiling mode | ||

| Main control parameters | 1)Water pouring time: 1~9999(s) adjustable; kettle back to origin time: 1~9999(s) adjustable | |

| 2)Water injection time: 1~9999(s) adjustable; cooling time: 1~9999(s) adjustable | ||

| 3)Withdraw conduction time: 1~9999(s) adjustable; withdraw break off time:1~9999(s) adjustable | ||

| 4)Rest set: 1~9999(times) adjustable; rest time: 1~9999(s) adjustable | ||

| 5)Test times: 1~9999(times) adjustable; actual | ||

| counting times: 1~9999(s) adjustable | ||

| Electric index | Power supply: 220V, 50Hz or 110V, 60Hz | |

| Machine power: about 500W (not including the power of the test sample) | ||

| Single station maximum load power: 4400W | ||

| Air pressure: 0.4~0.6 Mpa | ||

| Other | 1)Counting to alarm | |

| 2)No current alarm (boil water, dry heating, withdraw conduction) | ||

| 3)boil water/dry heating overtime alarm | ||

| 4)can adopt manual operation when the equipment failure, each station operate independently, without mutual influence. | ||